- Solfins, CAD/CAM, CAD, 3D CAD, CAM, SolidWorks, SolidCAM, Lantek, Logopress, Plastics, Electrical, Flow, Simulation, FEA, FEM.

- Enjoy the videos and music you love, upload original content, and share it all with friends, family, and the world on YouTube.

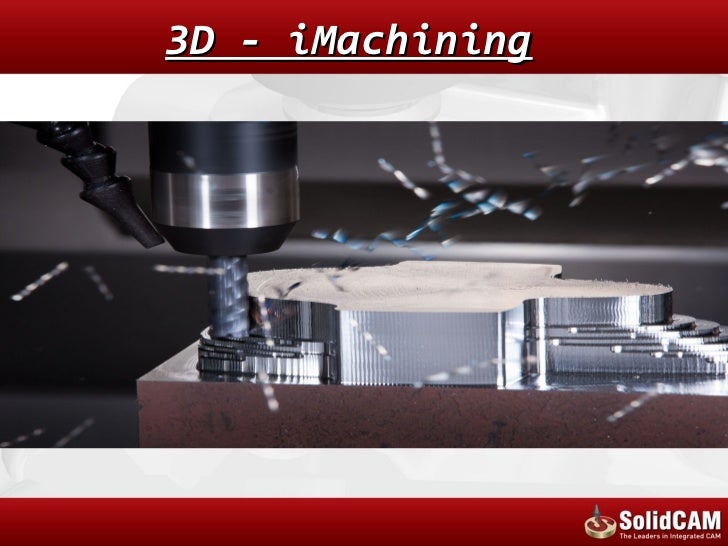

- SolidCAM HSR/HSM module is very powerful and market proven 3D high-speed machining modules for complex 3D parts, aerospace parts, molds, tools and dies. It offers unique machining and linking strategies for generating 3D high-speed toolpaths.

- SolidCAM 2013 Modules Overview: 3D Milling - Part 1 SolidCAMProfessor. Unsubscribe from SolidCAMProfessor? Cancel Unsubscribe. Subscribe Subscribed Unsubscribe 7.52K.

HSM provides powerful roughing and the finest finish tool paths available for 3D machining of complex 3D parts, aerospace parts, molds, tools and dies. HSR/HSM offers a high level of smoothness, efficiency, and smart machining.

HSR/HSM Modules for 3D High-Speed Milling

Powerful Roughing & Finishing Tool Paths for 3D Machining

- SolidCAM’s HSS provides smooth and powerful machining of localized surface areas and undercuts, using the standard as well as shaped tools.

- HSS provides easy selection of surfaces to be machined, without the need to define boundaries.

- HSS provides significantly increased surface quality.

- HSS is an essential module for every machine shop to machine all types of parts.

Powerful Roughing & Finishing Tool Paths for 3D Machining 3D machining at a very high level of smoothness, efficiency and smart machining. SolidCAM's HSR (High Speed Roughing) with HSM (High Speed Machining) module is very powerful and machine shop proven strategy for complex 3D parts, aerospace parts, molds, tools and dies.

People also looking at

1. SolidCAM Basics

2. CAM-Part

3. Tools

For easier identification and classification of tools, you can define your own tool types.

SolidCAM offers three default tool types, namely:

• Tool Rough Mill for rough cutters.

• Tool End Mill for finish cutters.

• Drill for drills, bores, reams, threading tools etc…

• Shaped Tool Drill for shaped drills, reams etc…

• Shaped Tool Rough for shaped rough cutters.

• Shaped Tool End Mill for shaped finish cutters

4. Geometry

SolidCAM enables you to turn 3D models, 2D and 3D sketches built with SolidWorks into G-code

for any CNC-machine. In this process of modelling to manufacturing, geometries have to be defined

to determine where the model will be machined.

In SolidCAM, you can define geometries in two places; in the Geometries field of the CAM-Manager

and in each job. Defining geometries in the Geometries field is only possible if the CAM-part uses

homes defined with Projections mode; otherwise, this field is inactive. It is recommended to define

the geometry from the Job dialog; this enables SolidCAM to check if the geometry follows the

necessary rules needed in this type of job.

The Geometries defined in SolidCAM are associative to the SolidWorks model. Any change made to

the model or sketch will propogate to referenced SolidCAM Geome

5. Jobs

This command enables you to add a new job to your CAM-Part. In SolidCAM a Job is a single

machining operation. Normally you manufacture a workpiece using several machining steps and

technologies. For each of these steps you can define a separate job. A job can be very complex, but

always uses one tool, one major geometry and executes one machining type, e.g. 3D milling, profile

milling or drilling.

You can edit any single machining operation, change the job sequence and generate G-Code, combining

and splitting the job-list of your CAM-Part.

6. 2.5D Milling

You can mill on or along a contour. The profile geometry can be either open or closed. In profile

milling you can optionally use tool radius compensation to the right or left side of the geometry.

SolidCAM offers two types of profiling:

• Milling a single profile to the specified constant or variable depth in one step or in several

user-defined down-steps.

• Concentric profiles to the specified constant or variable depth; this type of profiling

generates several concentric profiles that start from the defined clear offset distance from

the profile, and finishes on the profile geometry, thus clearing the area around the profile to

a constant depth.

7. 3D Milling

You can perform 3-axis gouge-free machining on solid and surface models. This Job offers a wide range of roughing, semi-finishing and finishing strategies for free-form models.

It can be used to manufacture molds, dies, electrodes,prototypes and other 3D Models.When you select the commands Add>3D Model, the 3D Model Job screen will be displayed.Select the 3D model geometry for the Job from the list.

8. Simulation

The SolidCAM simulation option enables you to check and view the generated tool path after you

have defined and calculated your machining operations. The simulation can help you avoid problems

such as mistakes in defining the jobs or selection of an unsuitable milling strategy you would otherwise

experience during the actual production run.

To simulate a Job, move the mouse on the Job and press the right mouse button in the CAM Manager.

The Job menu will be displayed. Click on the Simulate option

9. G-Code

This command enables you to generate and display the G-Code file for the CAM-Part or for machining

jobs. The G-Code file can then be transferred to your CNC-machine using a floppy disk, via a DNC

(RS 232) or Ethernet connection.

The format of the G-Code depends on the Controller you selected in the CAM-Part data dialog.

The G-Code output format can be customized either by using the GPP interface or by changing the

controller‘s *.mac and *.gpp files. Contact technical support for more information on post-processor

customization.

10. SolidCAM Settings

In the Settings dialog you can change the path to related applications, units, tolerances, default machines,

editors, and color settings for SolidCAM.

The Settings register enables you to easily view and edit the current program preferences and

options.

DOWNLOAD

Hidden content: ******, you can view after buying!

Solidcam 3d Milling Pdf

Price: CADCoin

Solidcam 3d Milling Tutorial

3d Milling Machine

You need login first!

Solidcam 3d Milling Software

If you have any questions, please feel free to EMail me: admin@cadfamily.com